- Home

- Mechanical processing

Mechanical processing Laser marking

Range of services CNC production

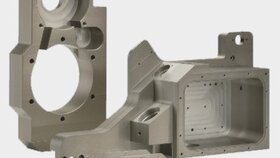

CNC milling

Our 3-axis and 5-axis machining centers from DMG and Hedelius enable us to manufacture with high precision for you. From the individual part to the smallest and small series production to large series, we realize for you in cost-optimized processes.

We can process components up to the dimensions 2000 x 500 x 400 mm for you on our CNC machines. A profile processing up to 3000 mm is not a challenge for us.

CNC turning

Our Traub CNC lathes with bar loader enable us to machine bar material up to a diameter of Ø 65 mm for you. From individual to large series production, we can map a wide variety of quantities for you. Thanks to our expertise in manufacturing and surface technology, we manufacture here for well-known traditional German companies from the medical technology sector, among others.

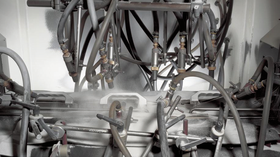

Saws

We offer you precise sawing work with the help of our high-speed saws from Emmegi and Pressta Eisele. Processing and cutting of material lengths of up to 6000 mm and a cutting width of up to 250 mm are perfectly placed with us. The subsequent further processing in our in-house surface technology is a synergetic process and represents an optimization of costs for you by reducing the necessary service partners.

Rohde’s processing and production division is characterised by state of the art plant and machinery. Profile processing through to mechanical production on machining centres with 3-5 axes is as much a part of Rohde AG’s current standard program as milling, lathing, sawing, bending, and welding using state of the art machines.

The comprehensive in-house surface treatment program enables the complete production of mechanical components, as well as high quality small and large-lot production runs at market friendly prices.

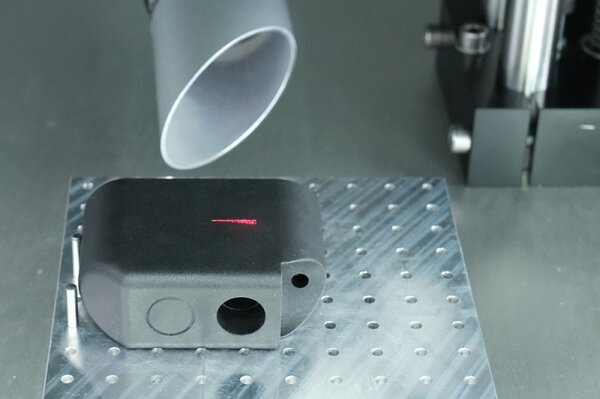

Laser marking

Laser marking

We laser a variety of materials and surfaces. The labeling field has a size of 100 x 100 mm. In addition, there is a rotary axis for labeling turned parts on the outer surface. Laser inscription is permanently abrasion-resistant and insensitive to chemicals and cleaning agents.

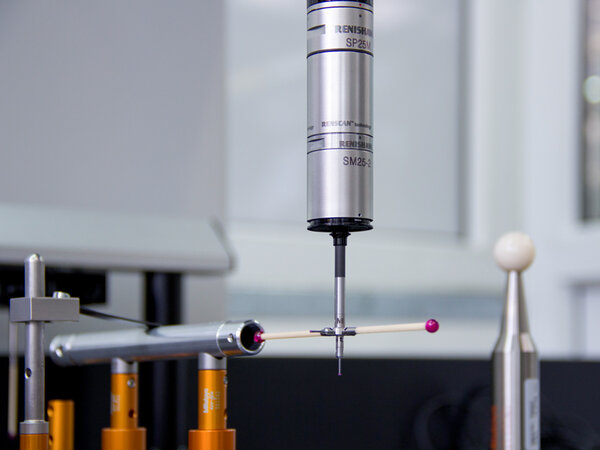

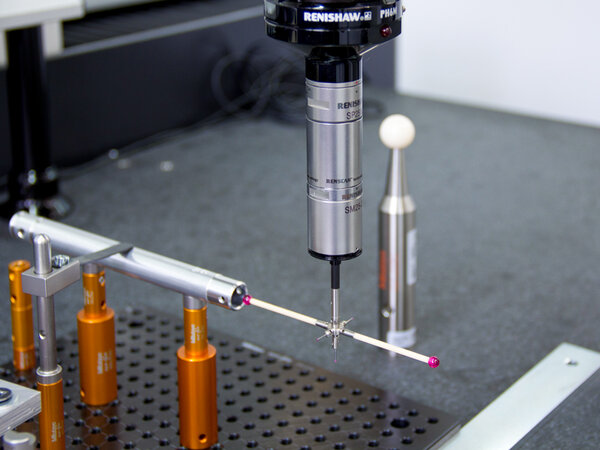

Quality assurance

3D measuring device for quality assurance.

Manufacturing certified according to DIN EN ISO 9001:2015.

Contacts

Milling, turning, sawing, bending, welding and assembly, laser marking

Lutz Schünemann

Tel.: +49 5503-9860-370

E-Mail: produktion@rohde-technics.com

Contact us

Rohde AG

Industriestrasse 9

D - 37176 Nörten-Hardenberg

Tel.: +49 (0) 5503 9860-0

Fax: +49 (0) 5503 9860-11

Opening hours (CET)