-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

- Thuis >>

- Oppervlaktetechniek >>

- Galvanische techniek

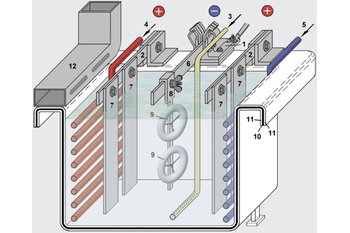

Galvanische techniek

Brief Specialist Information

For the designer in mechanical engineering and precision mechanics, but also for the interested professional buyer, knowledge of the physical relations involved in galvanization is of great use.

Lees meer

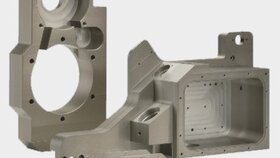

Electrogalvanizing of rack objects

For all kinds of machine components and technical items electrogalvanizing with varied chromating is still the most frequently-employed protection against corrosion.

Lees meer

Zinc / iron alloy plating

Galvanic zinc alloy plating has for years been established as a high-quality corrosion-control measure for iron and steel products.

Lees meer

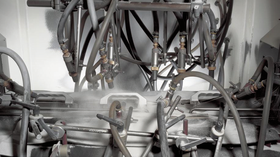

Electrogalvanizing of loose bulk goods

Articles of this kind (e.g. screws, nuts, bolts, smaller stampings etc.) are usually processed in rotating barrel electroplating machines (s. fig.).

Lees meer

Pearl-brightness chromium plating

The term is misleading because to be technically correct this process involves nickel plating with pearl-brightness (satin finish) and subsequent chromium plating.

Lees meer

High-gloss chromium plating

To be technically correct, this process – as is the case with pearl-brightness chromium plating – involves high-gloss nickel plating and subsequent chromium plating.

Lees meer

High-gloss and semi-gloss nickel plating

For many technical items one of the two above types of nickel plating is preferential to chromium plating for one or more of the following reasons:

Lees meer

Galvanic tin-plating

Tin is a silvery white, lustrous metal, whose shine does not become dulled, even during storage. It is highly resistant to atmospheric influences. With the exception of nitric acid, there are hardly any dilute inorganic and organic acids that attack it.

Lees meer

Contact

Rohde AG

Industriestrasse 9

D - 37176 Nörten-Hardenberg

Теl.: +49 (0) 5503 9860-0

Fax: +49 (0) 5503 9860-11

info@rohde-technics.com