- Thuis

- Oppervlaktetechniek

- Hard eloxeren

Hard eloxeren

Brief Specialist Information

Hard-Coat designates a procedure in which the surface of aluminium articles is provided with a protective layer by electro-chemical processes. It is an option to the regular anodizing process, which is used for a variety of parts made of aluminium.

Basically, in both of these procedures no impurity layer is applied to the surface of an item. Instead, it is a conversion of the aluminium-surface into an aluminium-oxide, which is microporous and therefore dyeable. With the standard anodizing procedure, aside from the protection of the surface against corrosion, an optically attractive appearance can be reached by using a corresponding pre-treatment. Simultaneously, there is a possibility of many different colourings.

Contrary to the standard anodizing process the protective layers, the protective layers obtainable with hard-coating are considerably harder and thicker – comparable to hard chrome layers – and hence they are preferably used for parts where it is specified by their technical application. Hard-coated layers possess a self-colouring capacity depending on the alloy and the layer thickness. Moreover, their porosity (absorbency of colourings) is significantly lower than with the regular anodizing procedure so that the possibility of the additional colouring is heavily reduced and limited to dark colour tones.

Hard-anodized layers possess no levelling effect, too, so that pits, scratches and damages will be visible after anodizing – therefore, as a rule, likewise a mechanical and/or chemical surface treatment is applied before, in order to eliminate such faults if high optical requirements are demanded. Both pre-treatment procedures involve material removal, though. Previously invisible inhomogeneities of the alloys also appear beyond the anodizing process and may cause optically disturbing structures.

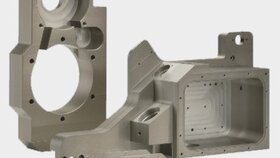

Hard-coating:

Due to the wide variety of article sizes (from small fine mechanical parts to large-surface tread plates), surface treatment is also manual or crane-operated. The different alloy types and geometries of the semi-finished products to be anodized do not permit automatic production.

Characteristics of Hard-Coating

- Hardness: 300 to 450 HV

- Layer thickness: up to 140 µm

- Material self-colouring capacity

- Wear-resistant – similar to hard-chrome

- Corrosion resistant against climatic influences and a multitude of chemicals

| Maximum workable size of item | |

| length: | 2.900 mm |

| breadth: | 400 mm |

| height: | 800 mm |

| weight: | 200 kg |

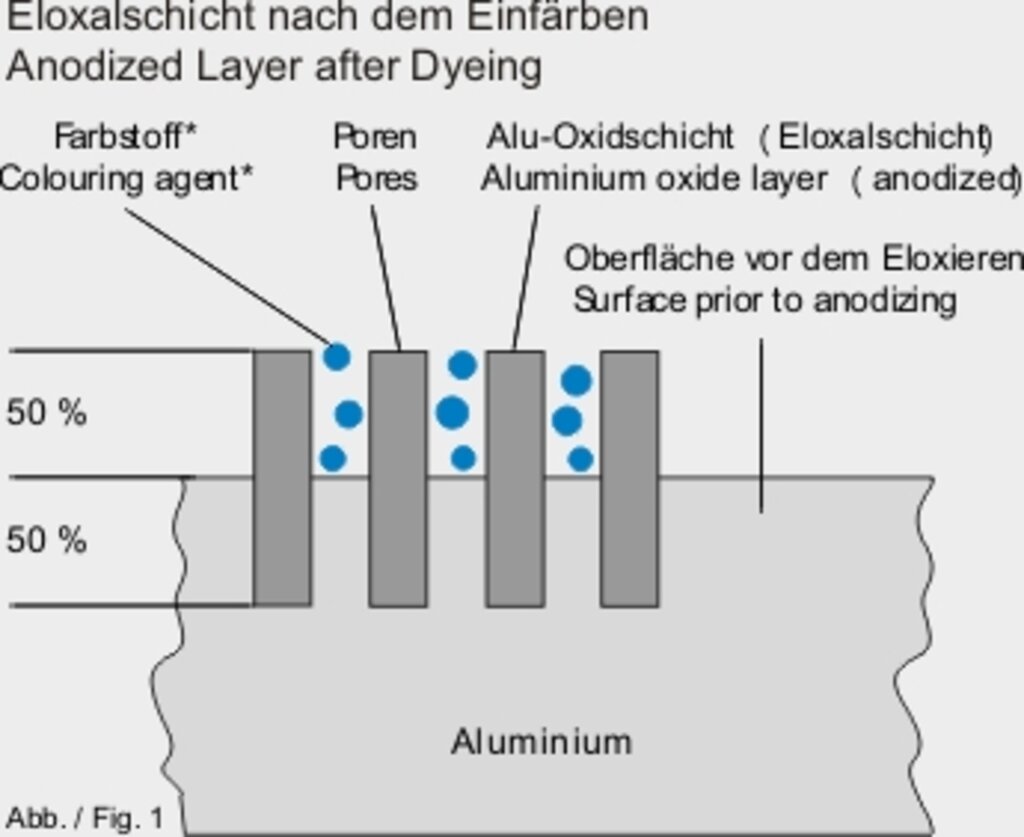

Abb. 1

Layer Build-Up

During the hard-anodizing process the oxide layer grows (different from decorative anodizing) forming columns to about 50% within the base material, the other 50% builds up externally.

The achievable layer thickness tolerance on hard anodized aluminium components is about ± 5 µm on the outer surface and decreases significantly in bores, hollow spaces and other areas based on the physical and geometrical condition.

A simplified diagram of the oxide layer build-up is figured aside.

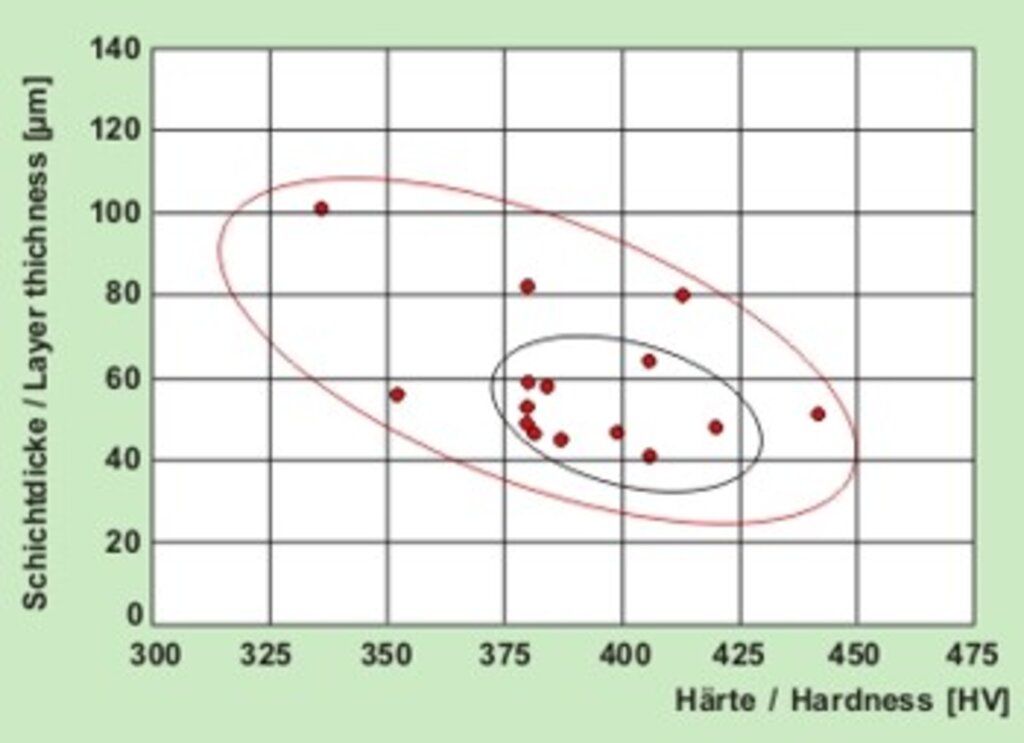

Härtebereich bei hochfester Aluminium-Legierung AlZn5,5MgCu

Hardness

The hardness achievable with hard-coating depends on the alloy and generally ranges between 300-450 HV.

For example, the illustrated Vickers-hardnesses against the thicknesses for the alloy AlZn5,5MgCu (former DIN-designation AIZnMgCu1.5) were ascertained during accomplished test sequences. This alloy is especially used for high-strength welding parts in centrifuge constructions.

The cluster-shaped distribution gets generated despite equal processing parameters due to fluctuations of tolerances of the alloy. On the alloy mentioned, usually required layer thicknesses of 40-60 µm normally possess a hardness between 375 and 425 HV.

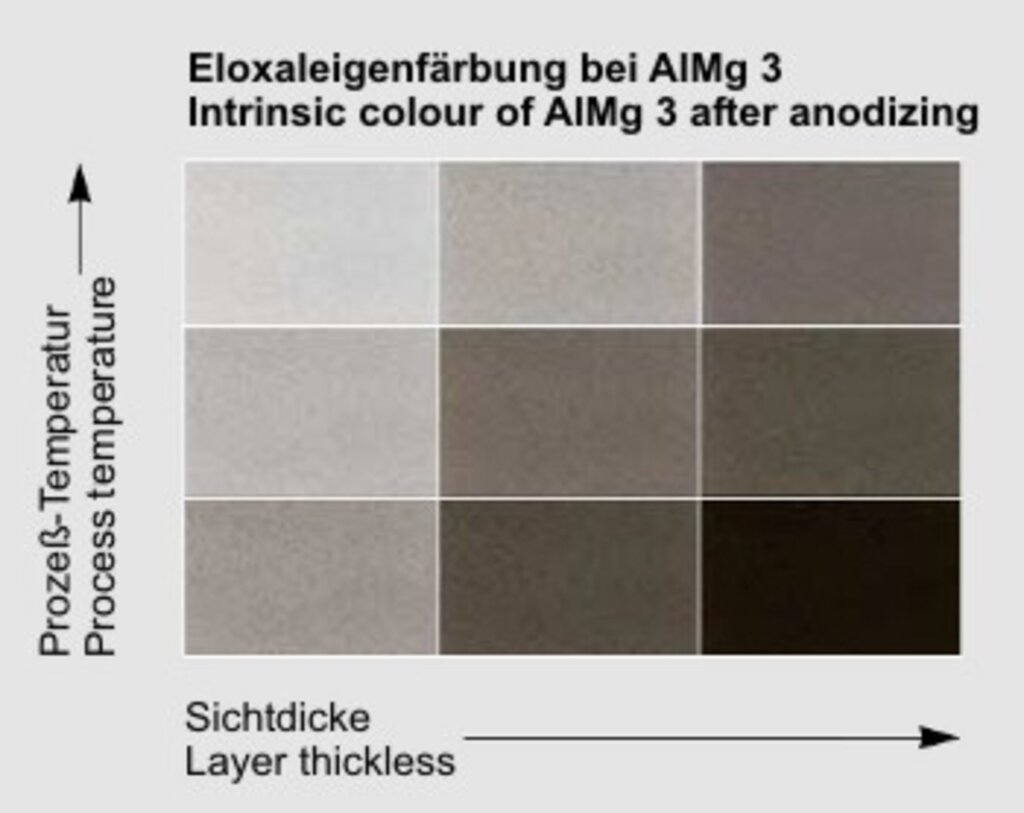

Aussehen der Harteloxal-Schichten

Appearance of Hard-Coated Layers

All hard-coated surfaces acquire an alloy depending intrinsic material colour during the anodizing-process. With the dependence on the layer-thickness and the treating temperature the following colours can be obtained:

grey to grey-brown

brown to dark brown

anthracite/titanium-coloured

natural black

Due to permitted varitions in alloy tolerances these colours are only partionally reproducible.

Colourability of Hard-Coated Layers

Controlled colouring after the hard-anodizing process is likewise alloy-dependent and possible in only a limited way in most cases. Due to the lower working temperatures of the hard-coating process, the obtained pore diameter is less than for the regular anodization. Consequently, the particles of the of the colouring medium usually have a bigger dia- meter, wherefore it is hard to penetrate into the bulit-up oxide layer.

The neccessary closure of the pores at standard hard-coating processes will be carried out in a finishing working-step (sealing) related to each application only.

Thus hard-coated components are usually used only for technical purposes and not for decorative ones.

Anodized layers, produced according to accerted standards, possess an excellent durability against industrial and sea athmospheres.

Anodizing coatings, which are made according the applies norms, have an excellent stability against industrial and sea atmospheres.

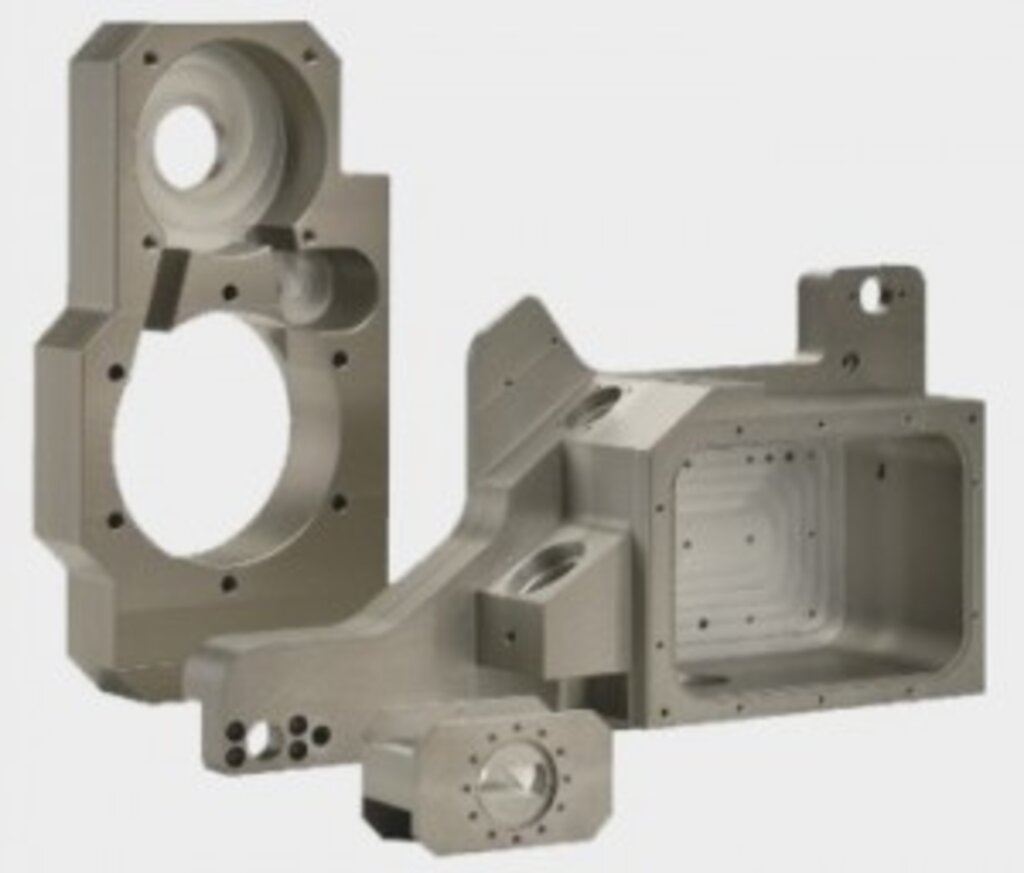

Example for surface treatment

Centrifugal item (AlZn5,5MgCu)

Rohteil, gleitgeschiffen

Harteloxiert mit Eigenfärbung, 60μm

Zusätzlich schwarz eingefärbt und verdichtet

Aluminium-Material-Datasheets

The recommendation for the anodizabilty of aluminium alloys aside is given according to the DIN data sheets.

EQ = Anodizing quality acc. to DIN 17611

• = Wear-resistant surfaces possible by hardcoating

– = at missing characteristics no further literature references available

Signification of characteristics:

1 = excellent

2 = good

3 = satisfactory

4 = inadequate

5 = not recommendable

6 = unsuitable

Anodizability:

D = decorative coating

S = protective coating

HC = Hardcoating

Quelle:

Aluminium-Material-Datasheets

Aluminium-Verlag

| Forgeable alloys DIN EN 573-3 | ||||||

| Eurostandard | DIN 1725-1 |

Designation | Anodizability | |||

| new | former | D | S | HC | ||

| EN AW-1050A | 3.0255 | Al99,5 | – | 2 (EQ=1) | 1 | – |

| EN AW-1070A | 3.0275 | Al99,7 | – | 1 | 1 | – |

| EN AW-1080A | 3.085 | Al99,8(A) | – | 1 | 1 | – |

| EN AW-1098 | 3.0385 | Al99,98 | Al99,98R | – | – | – |

| EN AW-1200 | 3.0205 | Al99,0 | – | 3 | 1 | – |

| EN AW-1350A | 3.0257 | EAl99,5(A) | E-Al | – | – | – |

| EN AW-2007 | 3.1645 | AlCu4PbMgMn | AlCuMgPb | – | 5 | • |

| EN AW-2011 | 3.1655 | AlCu6BiPb | AlCuBiPb | 6 | 5 | • |

| EN AW-2014 | 3.1255 | AlCu4SiMg | AlCuSiMn | 6 | 3 | – |

| EN AW-2017A | 3.1325 | AlCu4MgSi(A) | AlCuMg1 | 6 | 2 | – |

| EN AW-2024 | 3.1355 | AlCu4Mg1 | AlCuMg2 | 6 | 2 | – |

| EN AW-2117 | 3.1305 | AlCu2,5Mg | AlCu2,5Mg0,5 | – | – | – |

| EN AW-3003 | 3.0517 | AlMn1Cu | AlMnCu | 4 | 1 | – |

| EN AW-3004 | 3.0526 | AlMn1Mg1 | – | 4 | 1 | – |

| EN AW-3005 | 3.0525 | AlMn1Mg0,5 | – | 4 | 1 | – |

| EN AW-3103 | 3.0515 | AlMn1 | – | 4 | 1 | – |

| EN AW-3105 | 3.0505 | AlMn0,5Mg0,5 | – | – | – | – |

| EN AW-3207 | 3.0506 | AlMn0,6 | – | – | – | – |

| EN AW-5005 | – | AlMg1(B) | – | 3 | 1 | – |

| EN AW-5005A | 3.3315 | AlMg1(C) | AlMg1 | 2 (EQ=1) | 1 | – |

| EN AW-5019 | 3.3555 | AlMg5 | – | 4 | 1 | – |

| EN AW-5049 | 3.3527 | AlMg2Mn0,8 | – | 4 | 2 | – |

| EN AW-5041A | 3.3326 | AlMg2(B) | AlMg1,8 | – | – | – |

| EN AW-5052 | 3.3523 | AlMg2,5 | – | 2 | 1 | – |

| EN AW-5083 | 3.3547 | AlMg4,5Mn0,7 | AlMg4,5Mn | 4 | 2 | – |

| EN AW-5086 | 3.3545 | AlMg4 | AlMg4Mn | 3 | 1 | – |

| EN AW-5182 | 3.3549 | AlMg4,5Mn0,4 | AlMg5Mn | – | – | – |

| EN AW-5241 | 3.3525 | AlMg2 | AlMg2Mn0,3 | 4 | 1 | – |

| EN AW-5454 | 3.3537 | AlMg3Mn | AlMg2,7Mn | 4 | 2 | – |

| EN AW-5754 | 3.3535 | AlMg3 | – | 2 (EQ=1) | 1 | – |

| EN AW-6005A | 3.3210 | AlSiMg(A) | AlMgSi0,7 | 2 | 1 | – |

| EN AW-5012 | 3.0615 | AlMgSiPb | AlMgSiPb | bis 10µm | 3 | • |

| EN AW-6060 | 3.3206 | AlMgSi | AlMgSi0,5 | 1 (EQ) | 1 | – |

| EN AW-6061 | 3.3211 | AlMg1SiCu | – | 3 | 1 | – |

| EN AW-6082 | 3.2315 | AlSi1MgMn | AlMgSi1 | 3 | 1 | – |

| EN AW-6101B | 3.3207 | EAlMgSi(B) | E-AlMgSi0,5 | – | – | – |

| EN AW-7020 | 3.4335 | AlZn4,5Mg1 | AlZn4,5Mg1 | 3 | 2 | – |

| EN AW-7022 | 3.4345 | AlZn5Mg3Cu | AlZnMgCu0,5 | 6 | 2 | – |

| EN AW-7075 | 3.4365 | AlZn5,5MgCu | AlZnMgCu1,5 | 6 | 3 | – |

| EN AW-8011A | 3.0915 | AlFeSi(A) | AlFeSi | – | – | – |

Casting alloys DIN EN 1706 |

||||||

| Eurostandard | DIN 1725-1 |

Designation | Anodizability | |||

| new | former | D | S | HC | ||

| EN AC-21000 | 3.1371 | G-/GK-/GF-AlCu4MgTi | – | – | 3 | – |

| EN AC-21100 | 3.1841 | G-/GK-AlCu4Ti | – | – | 3 | – |

| EN AC-42100 | 3.2371 | G-/GK-/GF-AlSi7Mg0,3 | – | – | 4 | – |

| EN AC-42200 | – | AlSi7Mg0,6 | – | – | 4 | – |

| EN AC-43000 | 3.2381 | G-/GK-AlSi10Mg(a) | – | – | 5 | – |

| EN AC-43200 | 3.2383 | G-/GK-AlSi10Mg(Cu) | – | – | 5 | – |

| EN AC-43300 | 3.2373 | G-/GK-/GF-AlSi9Mg | – | – | 5 | – |

| EN AC-43400 | 3.2382 | G-/GK-/GF-AlSi10Mg(Fe) | – | – | 5 | – |

| EN AC-44000 | 3.2211 | G-/GK-AlSi11 | – | – | 5 | – |

| EN AC-44200 | 3.2373 | G-/GK-AlSi12(a) | – | – | 5 | – |

| EN AC-4300 | 3.2582 | GD-AlSi12(Fe) | – | – | 5 | – |

| EN AC-45000 | 3.2151 | G-/GK-AlSi6Cu4 | – | – | 4 | – |

| EN AC-46000 | 3.2163 | GD-AlSi9Cu3(Fe) | – | – | 5 | – |

| EN AC-46200 | 3.2163 | G-/GK-AlSi8Cu3 | – | – | 5 | – |

| EN AC-47000 | 3.2583 | G-/GK-AlSi12(Cu) | – | – | 5 | – |

| EN AC-47100 | 3.22982 | GD-AlSi12Cu1(Fe) | – | – | 5 | – |

| EN AC-48000 | – | GK-AlSi12CuNiMg | – | – | 5 | – |

| EN AC-51100 | 3.3541 | G-/GK-/GF-AlMg3(a) | – | – | 1 | – |

| EN AC-51200 | 3.3292 | GD-AlMg9 | – | – | 2 | – |

| EN AC-51300 | 3.3561 | G-/GK-AlMg5 | – | – | 1 | – |

| EN AC-51400 | 3.3261 | G-/GK-AlMg5(Si) | – | – | 2 | – |

| EN AC-71000 | – | AlZn5Mg | – | – | 2 | – |

Casting alloys DIN EN 1725 (replaced by DIN EN 1706) |

||||||

| Eurostandard | DIN 1725-1 |

Designation | Anodizability | |||

| new | former | D | S | HC | ||

| – | 3.2581 | G-/GK-AlSi12 | – | 6 | 4 | 4 |

| – | 3.2583 | G-/GK-AlSi12(Cu) | – | 6 | 4 | 4 |

| – | 3.2381 | G-/GK-AlSi10Mg | – | 4 | 3 | 4 |

| – | 3.2383 | G-/GK-AlSi10Mg(Cu) | – | 6 | 4 | 4 |

| – | 3.2163 | G-/GK-AlSi9Cu3 | – | 6 | 6 | 4 |

| – | 3.2153 | G-/GK-AlSi6Cu4 | – | 6 | 6 | 4 |

| – | 3.2211 | G-/GK-AlSi11 | – | 6 | 4 | 4 |

| – | 3.2373 | G-/GK-AlSi9Mg | – | 6 | 4 | 4 |

| – | 3.2371 | G-/GK-/GF-AlSi7Mg | – | 6 | 4 | 4 |

| – | 3.1841 | G-/GK-AlCu4Ti | – | 6 | 5 | 4 |

| – | 3.1371 | G-/GK-/GF-AlCu4TiMg | – | 6 | 5 | 4 |

| – | 3.3541 | G-/GK-/GF-AlMg3 | – | 1 | 1 | 1 |

| – | 3.3241 | G-/GK-/GF-AlMg3Si | – | 2 | 1 | 1 |

| – | 3.3561 | G-/GK-AlMg5 | – | 1 | 1 | 1 |

| – | 3.3261 | G-/GK-AlMg5Si | – | 2 | 1 | 1 |

| – | 3.2341 | G-/GK-AlSi5Mg | – | 4 | 2 | 3 |

| – | 3.2163 | GD-AlSi9Cu3 | – | 6 | 6 | 4 |

| – | 3.2982 | GD-AlSi12(Cu) | – | 6 | 6 | 4 |

| – | 3.2582 | GD-AlSi12 | – | 6 | 5 | 4 |

| – | 3.2382 | GD-AlSi10Mg | – | 6 | 4 | 4 |

| – | 3.3292 | GD-AlMg9 | – | 4 | 2 | 2 |

Contact

Rohde AG

Industriestrasse 9

D - 37176 Nörten-Hardenberg

Теl.: +49 (0) 5503 9860-0

Fax: +49 (0) 5503 9860-11

info@rohde-technics.com