-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

- Uchwyty przemysłowe

-

Automatyzacja

-

Łączniki rurowe

-

Obróbka powierzchniowa

-

Malowanie proszkowe

Malowanie proszkowe -

Galwanizernia

Galwanizernia -

Eloksalowanie

Eloksalowanie -

Eloksalowanie twarde

Eloksalowanie twarde -

Polerowanie elektrolityczne produktów ze stali szlachetnej

Polerowanie elektrolityczne produktów ze stali szlachetnej -

Czyste bejcowanie aluminiowych elementów montażowych

Czyste bejcowanie aluminiowych elementów montażowych -

Aluminiowa powłoka konserwacyjna

Aluminiowa powłoka konserwacyjna -

Niewielkie ilości – obróbka pojedynczych elementów

Niewielkie ilości – obróbka pojedynczych elementów -

Szlifowanie, szczotkowanie i polerowanie

Szlifowanie, szczotkowanie i polerowanie -

Obróbka strumieniowa szklanymi kulkami oraz śrutem stalowym

Obróbka strumieniowa szklanymi kulkami oraz śrutem stalowym -

Bębnowanie (obróbka wibrościerna)

Bębnowanie (obróbka wibrościerna)

-

- Obróbka mechaniczna

-

Aktualności

-

Firma

- Strona główna >>

- Obróbka powierzchniowa >>

- Obróbka strumieniowa szklanymi kulkami oraz śrutem stalowym

Glass Ball and Steel-Grit Blasting

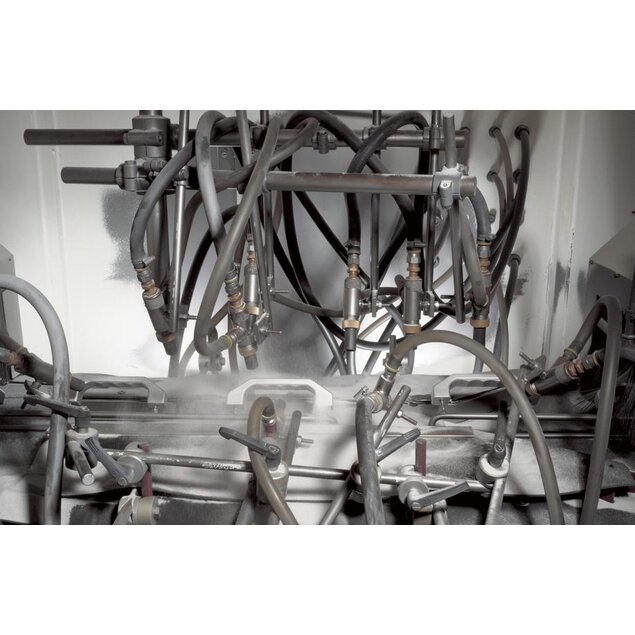

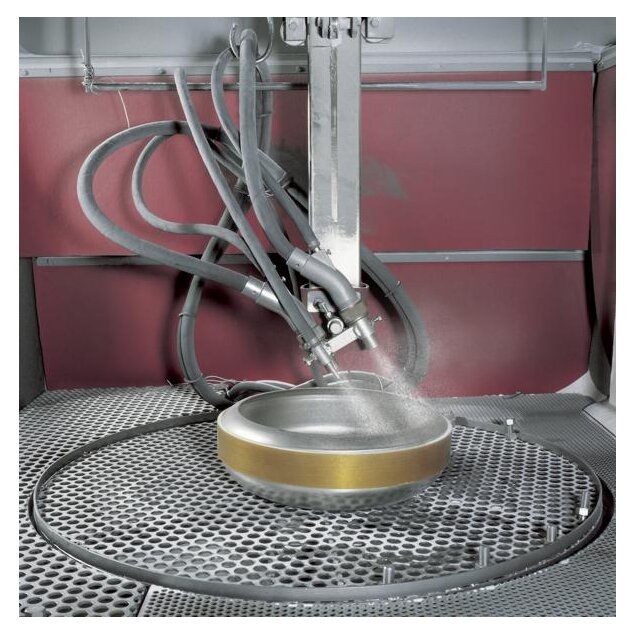

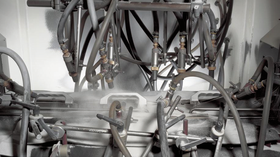

View into the blasting cabin of an automatic glass-ball blasting machine; aluminium handles in continuous blasting

Blasting is one of the most important processes to produce even dull-finished or satin- finished surfaces before electroplating or anodizing. Here, glass-ball blasting with ball diameters of approx. 70-100 µm is the most frequently used process for decorative aluminium surfaces. Depending on the requirements and purpose, it is suitable also for steel, stainless steel and nonferrous metal.

In particular, camera housing and objective rings and also stainless-steel products and aluminium handles, such as those illustrated here, acquire their attractive appearance in this process.

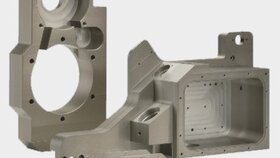

Apart from glass-ball blasting in a continuous operation and by means of automatic rotary tables and manual installations we also offer steel-grit blasting in the automatic centrifugal jet machinery as pre-treatment for scaled or welded steel parts and castings.

| Maximum workable size of item in mm | |||

| Length | Width | Height | |

| Glass-ball blasting in continuous process |

2500 | 250 | 200 |

| Glass-ball blasting in manual operation |

800 | 250 | 400 |

| Glass-ball blasting in automatic turntable machine |

Ø230 | 450 | |

| Glass-ball blasting in Satellite blasting machine |

Ø200 | 400 | |

| Steel-grit blasting in centrifugal jet machine |

Ø800 | 300 | |

Kontakty na świecie

Rohde AG

Industriestrasse 9

D - 37176 Nörten-Hardenberg

Tel.: +49 (0) 5503 9860-0

Faks: +49 (0) 5503 9860-11

info@rohde-technics.com