-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

-

SR.navbar.languageswitch.texthide

- Uchwyty przemysłowe

-

Automatyzacja

-

Łączniki rurowe

-

Obróbka powierzchniowa

-

Malowanie proszkowe

Malowanie proszkowe -

Galwanizernia

Galwanizernia -

Eloksalowanie

Eloksalowanie -

Eloksalowanie twarde

Eloksalowanie twarde -

Polerowanie elektrolityczne produktów ze stali szlachetnej

Polerowanie elektrolityczne produktów ze stali szlachetnej -

Czyste bejcowanie aluminiowych elementów montażowych

Czyste bejcowanie aluminiowych elementów montażowych -

Aluminiowa powłoka konserwacyjna

Aluminiowa powłoka konserwacyjna -

Niewielkie ilości – obróbka pojedynczych elementów

Niewielkie ilości – obróbka pojedynczych elementów -

Szlifowanie, szczotkowanie i polerowanie

Szlifowanie, szczotkowanie i polerowanie -

Obróbka strumieniowa szklanymi kulkami oraz śrutem stalowym

Obróbka strumieniowa szklanymi kulkami oraz śrutem stalowym -

Bębnowanie (obróbka wibrościerna)

Bębnowanie (obróbka wibrościerna)

-

- Obróbka mechaniczna

-

Aktualności

-

Firma

- Strona główna >>

- Obróbka powierzchniowa >>

- Eloksalowanie

Eloksalowanie

Mały podręcznik

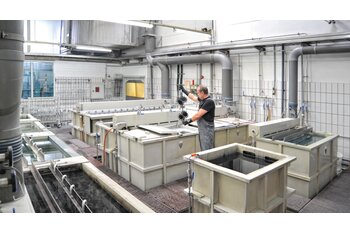

Rohde already has a nearly 60-year tradition of surface treatment on high-quality precision goods made of aluminium and its alloys. Here, anodizing with or without dyeing is by far the most popular form of protection against corrosion.

Czytaj więcej

Artykuły precyzyjne dla przemysłu optycznego

Basically, the colour anodizing on parts of this kind and of the types on the following pages 32-36 is used in manually-operated machineries.

Czytaj więcej

Artykuły precyzyjne dla techniki ortopedycznej

As already highlighted on the reverse side, these articles can only be processed to a high quality on manually-operated machinery, too.

Czytaj więcej

Elementy dla wirówek laboratoryjnych

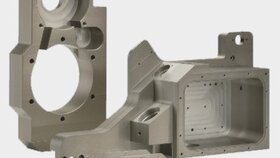

Components of this kind in a wide variety of versions rank among the most precise and expensive individual parts in a centrifuge.

Czytaj więcej

Ciężkie elementy sypkie

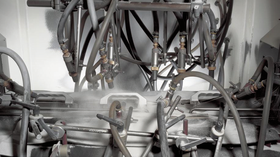

Small bulk goods of aluminium, which are not stackable (e.g. rivets, screws, lathe-cut parts) can be anodized as "loose goods” in a similar manner like at barrel galvanizing.

Czytaj więcej

Małe elementy wieloseryjne

As far as it is technically possible or justifiable, articles like the aluminium stampings illustrated here can be anodized in large quantities simultaneously.

Czytaj więcej

Profile wytłaczane, Elementy konstrukcyjne i fasadowe

For quality reasons, anodized aluminium sections, pre-treated by grinding, brushing or polishing, are still used today, especially in interior finishing work. Due to the diverse shapes of these sections, a lot of manual work requiring specialist experience is involved.

Czytaj więcej

Anodyzacja tytanowa

The electrolytic production of an oxide layer on titanium and titanium alloys is done in accordance with the international standard for aerospace (Specification LN 29747).

Czytaj więcej

Kontakty na świecie

Rohde AG

Industriestrasse 9

D - 37176 Nörten-Hardenberg

Tel.: +49 (0) 5503 9860-0

Faks: +49 (0) 5503 9860-11

info@rohde-technics.com