- Home

- Trattamento delle superfici

Trattamento delle superfici

Rivestimento in polvere

In powder coating, a powder coating is applied to a workpiece using electrostatic forces and fused there by the effect of heat to form a solid, protective layer. In this way, surfaces are...

Leggi altro

Galvanizzazione

Brief Specialist Information For the designer in mechanical engineering and precision mechanics, but also for the interested professional buyer, knowledge of the physical relations involved in galvanization is of great use. Fig. 1: Setup of a Galvani…

Leggi altro

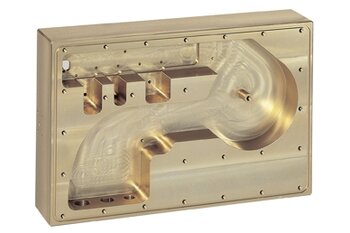

Anodizzazione

Brief Specialist Information Rohde already has a nearly 60-year tradition of surface treatment on high-quality precision goods made of aluminium and its alloys. Here, anodizing with or without dyeing is by far the most popular form of protection agai…

Leggi altro

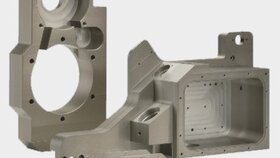

Anodizzazione dura

Hard-Coat designates a procedure in which the surface of aluminium articles is provided with a protective layer by electro-chemical processes. It is an option to the regular anodizing process, which is used for a variety of parts made of aluminium.

Leggi altro

Elettrolucidatura di prodotti in acciaio inox

With this material erosive, electrolytical process unevenness on the surface of the metal can be levelled out and sharp edges deburred;

Leggi altro

Pulizia mediante decappaggio di componenti d’alluminio

Machined mechanical components, which have to be assembled under clean-room conditions must be free of surface impurities.

Leggi altro

Rivestimenti in alluminio di conversione

This process concerns about a replacement fort the transparent resp. yellow chromating.

Leggi altro

Piccole quantità – Singola lavorazione

Small series and/or individual parts for which an electroplating finish is not possible in automatic machinery or is too elaborate are processed on manually operated machineries in the Rohde factory in Göttingen, where there is equipment for bulk goods and also for individual processing of ”rack-items” available.

Leggi altro

Rettifica, spazzolatura e lucidatura

Even today, mechanical pre-treatment such as the above necessitates a high degree of manual work, depending on the articles and quantities involved; expertise is the most important prerequisite.

Leggi altro

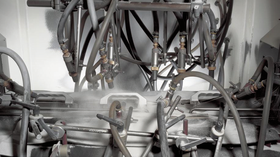

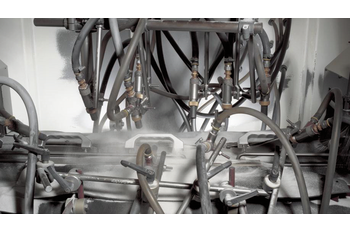

Pallinatura con sfere di vetro e granigliatura

Blasting is one of the most important processes to produce even dull-finished or satin- finished surfaces before electroplating or anodizing. Here, glass-ball blasting with ball diameters of approx.

Leggi altro

Vibrofinitura (trovalizzazione)

One of the most customary processes to deburr and/or precision-grind the surfaces of loose bulk items and machine components is vibratory grinding.

Leggi altro

Contatti

Rohde AG

Industriestrasse 9

D - 37176 Nörten-Hardenberg

Tel.: +49 (0) 5503 9860-0

Fax: +49 (0) 5503 9860-11

Opening hours (CET)